Rated Thermal Power :0.35MW ~ 14MW

Working Pressure :0.7/1.0 MPa

Thermal Efficiency :91% ~ 93%

Avaliable Fuel :LPG, NG, Diesel, Oil

Application : Central Heating Boiler ,Pharmaceuticals Industry ,Chemical Industry Boiler ,Brewery Industry Boiler

Email : info@xinliboiler.com

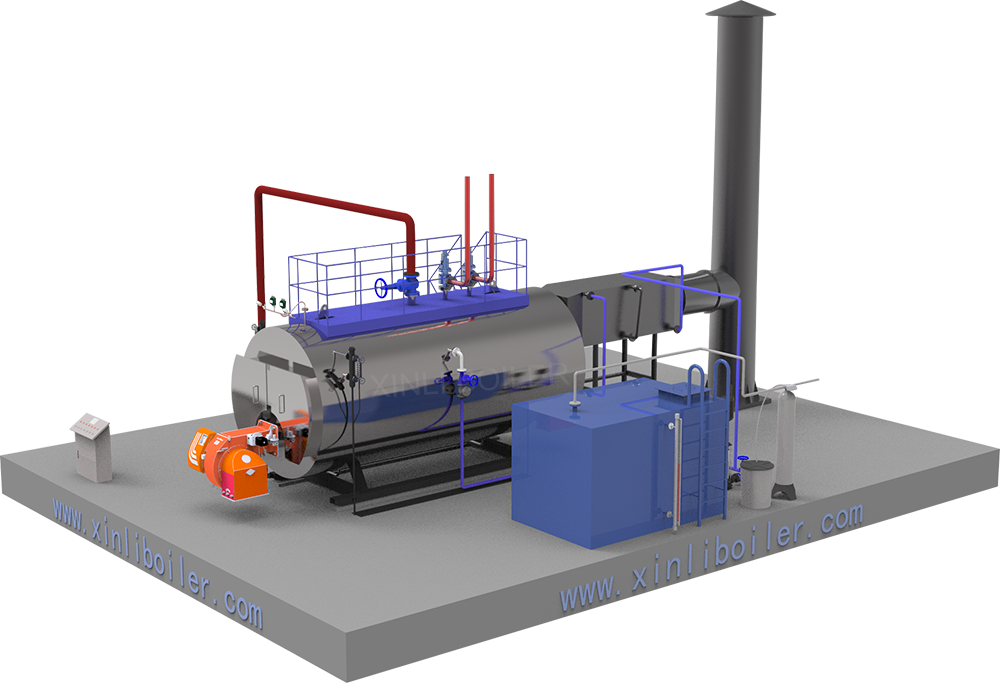

Horizontal type oil gas fire tube hot water boiler is a kind of safe and high efficiency heating equipment with full automatic control system. This series oil gas fired boiler is horizontal type fast assembly fire tube boiler with three pass structure, it has compact structure, small volume, strong load adaptability and low water quality requirement. This boiler adopts wet wet back structure, it can adapt to the high temperature, has a good sealing, increase the radiation heat transfer area and improve the heat transfer efficiency. It is widely used for central heating in greenhouse, enterprise, hotel, hospital, civil architecture, etc.

Equipped with high quality and reliable international brand burner, the fuel could burn sufficiently, high combustion efficiency, low harmful gas emission and noiseless operation.

Adopts horizontal type three pass structure and large diameter corrugated furnace. Large combustion space, the fuel could burn sufficiently. The large radiant heating surface to ensure the high thermal efficiency.

The smoke box is double door design, open conveniently. It uses multistage labyrinth seal technology, the seal material is special, has good compressibility, no smoke leakage.

Equipped with explosion proof equipment at the back of boiler, prevent deflagration in furnace, discharge high energy, and automatic reset as well, to ensure the boiler operate safety and efficiently.

The boiler shell use aluminium silicate board for heat preservation, the thickness of board is 8cm, high thermal shielding efficiency but low heat loss, to increase the boiler thermal efficiency.

has the protection function of water shortage, over pressure, over temperature, gas leakage, flame out, electric leakage, and phrase-lacking or overloading of motor, etc.,to ensure boiler safe operation.

Equipped with economizer, make full use of the heat of flue gas, decrease the exhaust smoke temperature, the thermal efficiency could be increased to as high as 98%.

| Model | Rated Thermal Power (MW) | Rated Pressure (MPa) | Thermal Efficiency (%) | Fuel Consumption | Overall Dimension of biggest part for transfortation (kg) | Weight of biggest part for transporation L×W×H (m) | ||

| Light Oil (kg/h) | Lpg (Nm3/H) | Coal Gas (Nm3/H) | ||||||

| WNS 1.05-0.7-Y(Q) | 1.05 | 0.7 | 91~93 | 98.5 | 119.4 | 253.7 | 3400 | 3.5×1.8×2.05 |

| WNS 1.75-0.7-Y(Q) | 1.75 | 1.0 | 91~93 | 164.2 | 198.9 | 422.8 | 4800 | 4.5×1.95×2.3 |

| WNS 2.1-0.7-Y(Q) | 2.1 | 1.0 | 91~93 | 197 | 238.7 | 507.3 | 6682 | 4.8×2×2.5 |

| WNS4.2-0.7-Y(Q) | 4.2 | 1.0 | 91~93 | 394 | 477.5 | 1014.6 | 12400 | 7.85×2.75×3.46 |

| WNS7-0.7-Y(Q) | 7 | 1.0 | 91~93 | 656.7 | 795.8 | 1691 | 15300 | 8.6×3.77×4.15 |

| Note: Parameter is for reference only, if any changes should follow the actual drawing | ||||||||

Saudi Arabia | Gas Fired Steam Boiler

Saudi Arabia | Gas Fired Steam Boiler

Saudi Arabia | Gas Fired Steam Boiler

Saudi Arabia | Gas Fired Steam Boiler

Zimbabwe | Zimbabwe

Zimbabwe | Zimbabwe

UK | Coal Fired Chain Grate Steam Boiler

UK | Coal Fired Chain Grate Steam Boiler