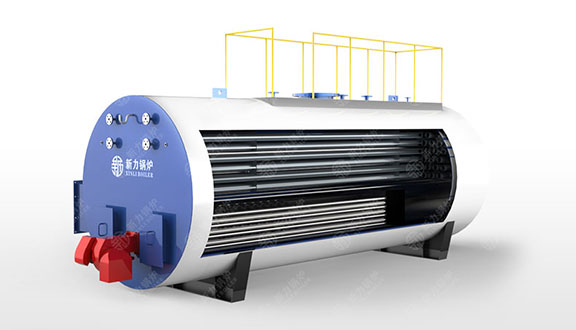

Rated Evaporation Capacity :400~2500KW

Working Pressure :0.4~1Mpa

Thermal Efficiency :85%~88%

Avaliable Fuel :Natural gas crude oil diese

Application : Food & Beverage Industry Boiler ,Brewery Industry Boiler ,Chemical Industry Boiler ,Pharmaceuticals Industry ,Textile Industry Boiler ,Central Heating Boiler

Email : info@xinliboiler.com

The combustion chamber, heating furnace with low level design, make the safety range of water level increases. This series heater is a wet back type , two return , a full Corrugated furnace. Furnace shell insulation adopts 0.8mm stainless steel plate, which is beneficial to the heater in the harsh environment prolong furnace life. For the convenience of operation, maintenance and reduce the heating furnace area, heating furnace is provided with a front door, a rear smoke box, using a combined open cigarette box door, repair maintenance is very convenient.

This series heater is coposed by heater and heat exchanger Heat exchanger with burning chamber integrated,Burning chamber and heat exchanger are all in one Enclosed container,adopt burning chamber and heating surface low level design.

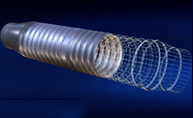

Furance is two,three way wet back structure,large Corrugated furnace and full threaded pipe not only increase the heating surface also has good expansion performance can effectively reduce the thermal stress during operation ,increase heater life.

The smoke box adopts movable whole cigarette box cover, smoke box cover using labyrinth design, is not easy to be burnt, no leakage of smoke. The box door is using high temperature aluminum silicate material, flexible switch, convenient maintenance.

The control system is a man-machine interface, programmable PLC, and key electrical components adopt international brands such as German Siemens, Japan Mitsubishi and OMRON to ensure the reliability of the control system.

According to the thermal power, heating furnace diameter and considering full load operation, the burner adjustment ratio is 1:3. Proportional regulation makes the heater have greater overload capacity to ensure efficient and stable operation.

The boiler operates in a fully enclosed state without water supply. If softened water is added, there is no dirty submerged water in the drum. Reduce stress corrosion due to dirt and prolong service life

Model / Item | HJ 400-YQ/ 1.0-Q | HJ 630-YQ/ 1.0-Q | HJ 800-YQ/ 1.0-Q | HJ 1000-YQ/ 1.0-Q | HJ 1250-YQ/ 1.0-Q | HJ 1600-YQ/ 1.0-Q | HJ 1750-YQ/ 1.0-Q | HJ 2000-YQ/ 1.0-Q | HJ 2500-YQ/ 1.0-Q | |

| Heated medium | Well product crude oil | Well product crude oil | Well product crude oil | Well product crude oil | Well product crude oil | Well product crude oil | Well product crude oil | Well product crude oil | Well product crude oil | |

| Rated power | KW | 400 | 630 | 800 | 1000 | 1250 | 1600 | 1750 | 2000 | 2500 |

| Shell bearing pressure | Mpa | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Pipeline pressure | Mpa | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Inlet/outlet temperature | ℃ | 40/70 | 40/70 | 40/70 | 40/70 | 40/70 | 40/70 | 40/70 | 40/70 | 40/70 |

| Fire tube chimney area | ㎡ | 25 | 39.5 | 51 | 61.3 | 67.3 | 76.6 | 81.7 | 96.5 | 117.3 |

| Coil area | ㎡ | 47.3 | 70.8 | 94.2 | 119.2 | 147.1 | 188.2 | 206 | 235.4 | 287.6 |

| Dimensions | ㎜ | φ1600*5250 | φ1800*5600 | φ1800*5600 | φ2000*6600 | φ2000*6600 | φ2400*6800 | φ2600*6800 | φ2800*7000 | φ3200*7400 |

| Metal weight | T | 5.9 | 7.1 | 8.33 | 9.4 | 11.7 | 14.8 | 16.8 | 19.7 | 23.2 |

| Fuel type | Natural gas crude oil diesel | Natural gas crude oil diesel | Natural gas crude oil diesel | Natural gas crude oil diesel | Natural gas crude oil diesel | Natural gas crude oil diesel | Natural gas crude oil diesel | Natural gas crude oil diesel | Natural gas crude oil diesel | |

| Thermal efficiency | % | 85 | 85 | 86 | 86 | 86 | 88 | 88 | 88 | 88 |

Saudi Arabia | Gas Fired Steam Boiler

Saudi Arabia | Gas Fired Steam Boiler

Saudi Arabia | Gas Fired Steam Boiler

Saudi Arabia | Gas Fired Steam Boiler

Zimbabwe | Zimbabwe

Zimbabwe | Zimbabwe

UK | Coal Fired Chain Grate Steam Boiler

UK | Coal Fired Chain Grate Steam Boiler